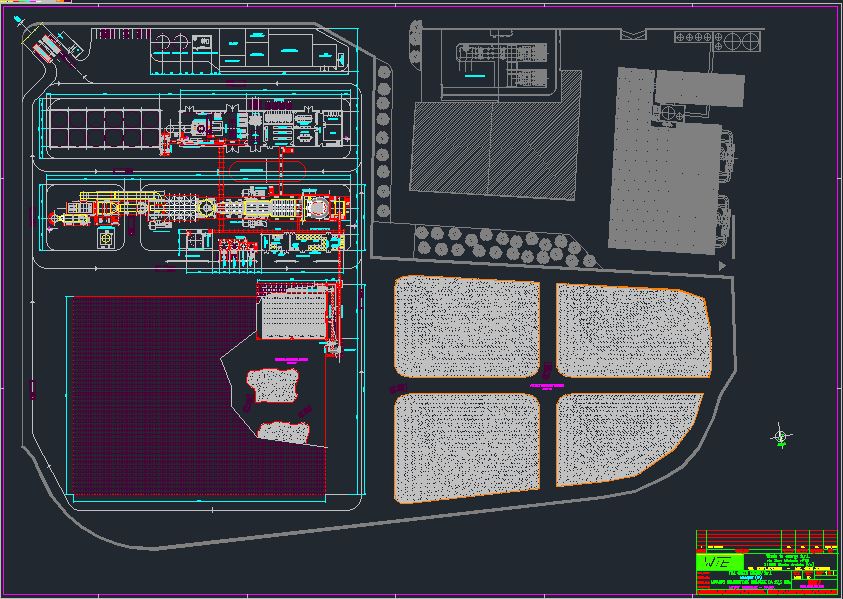

Design, supply and start-up of control logics for biogas handling and related burners system

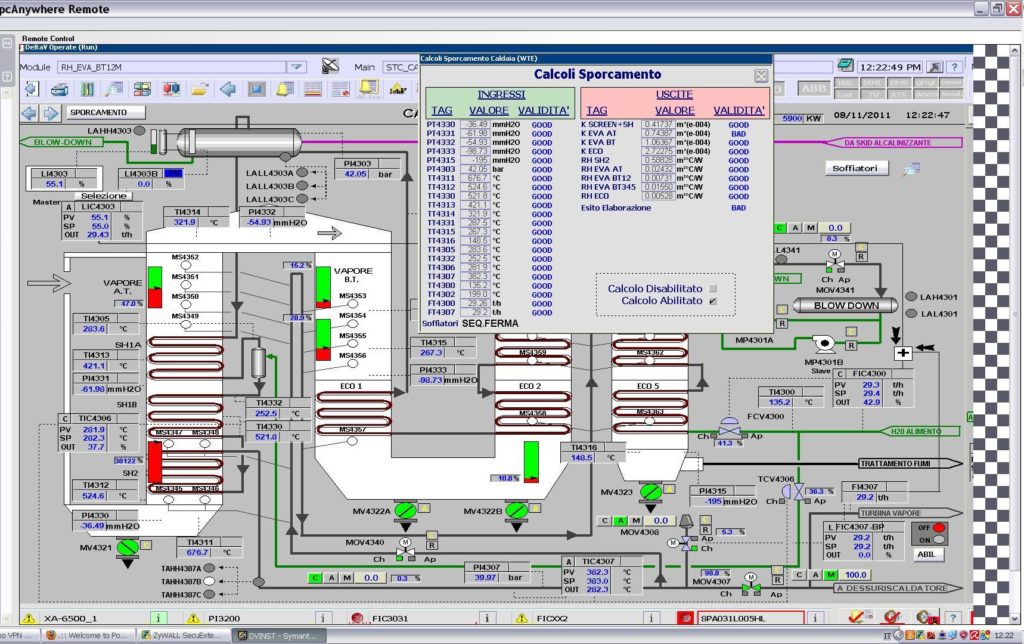

Design, engineering, start-up and testing of a new control system, to be applied on an anaerobic digestion plant, on following biogas handling and on related burners, already installed in a biomass furnace.