Design and basic engineering

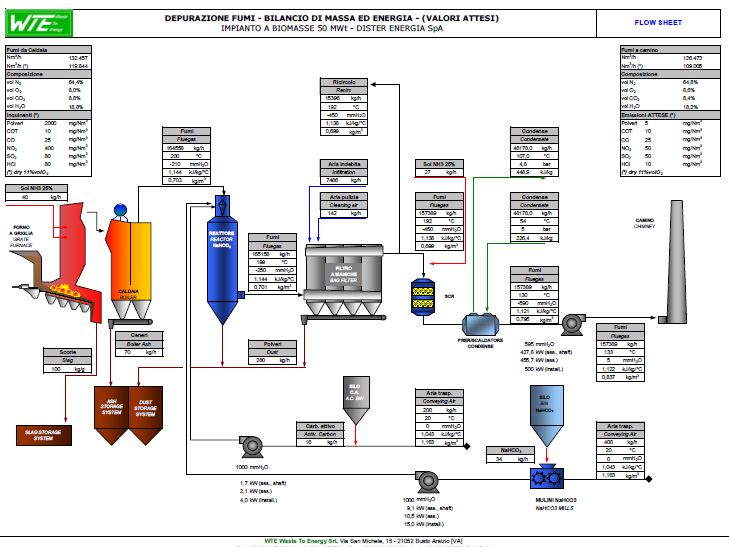

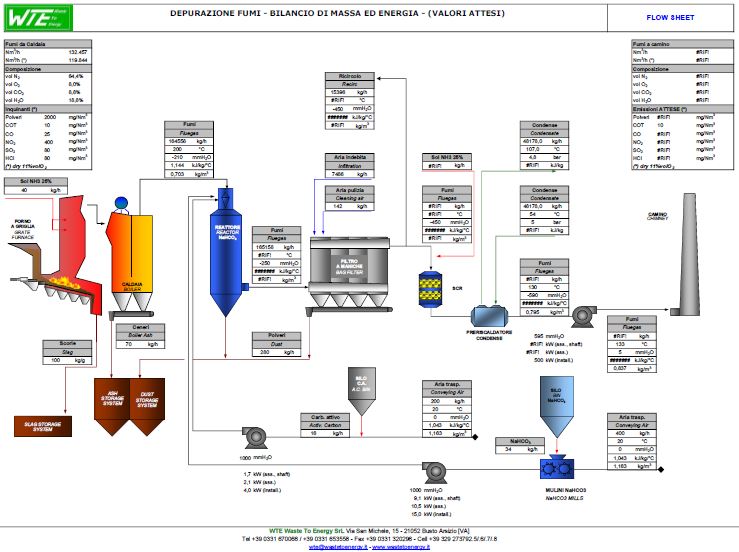

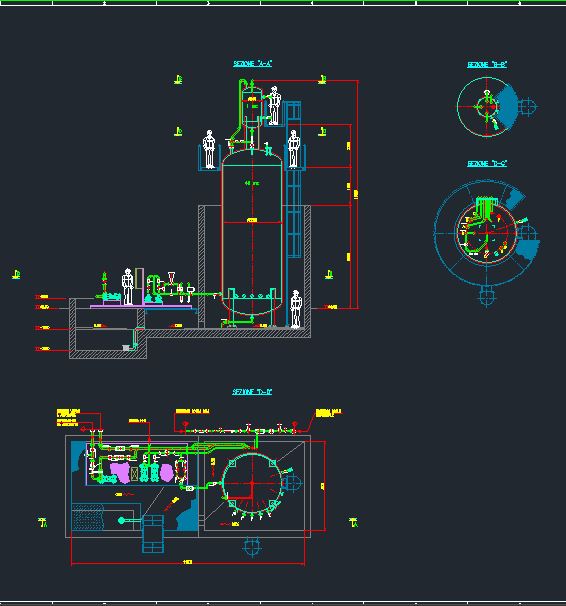

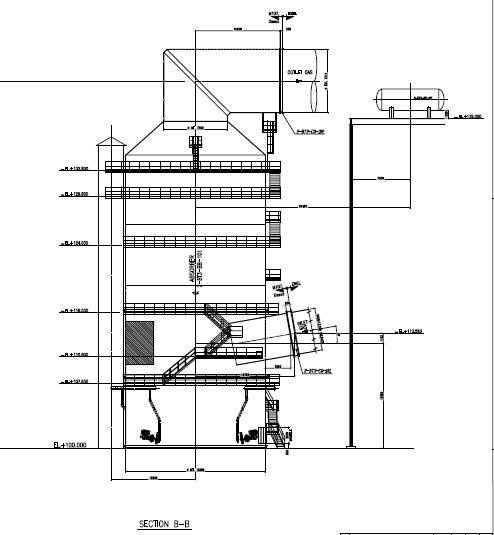

The client, owner of the wte plant Silla2 in Milan, appointed W.T.E. to provide a solution for the treatment of the primary air, drawn from the refuse pit of the plant. WTE designed a system in two stages. A self-cleaning filter, operating as metallic sieves, was recommended. As the plant needed a deeper cleaning system …