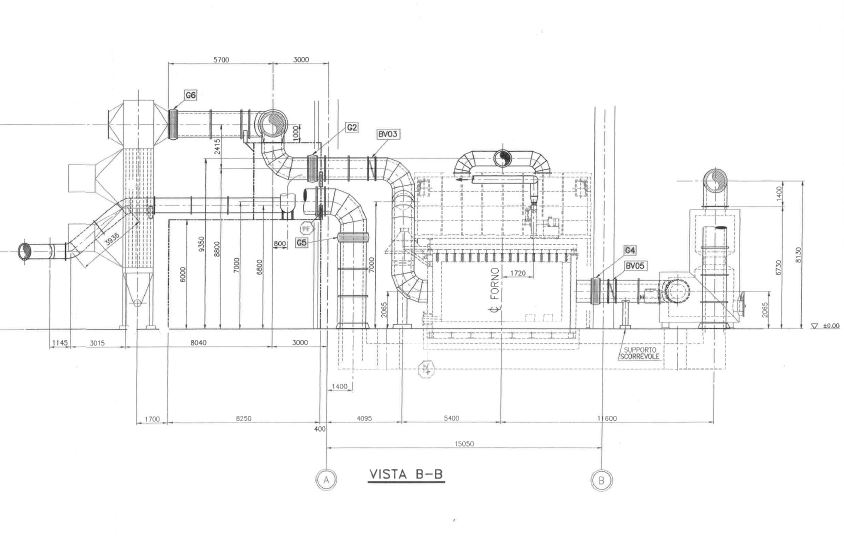

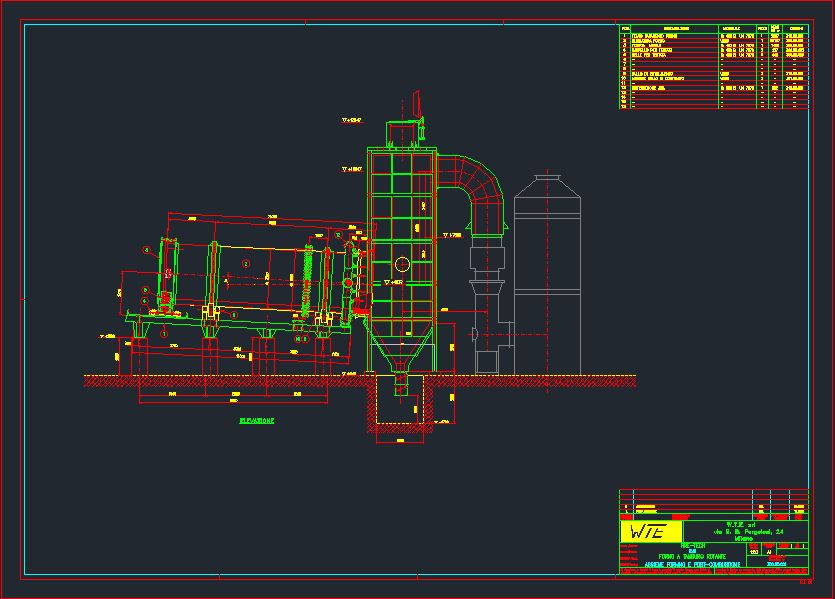

Repowering of biomass boiler in a chemical factory.

W.T.E. delivered basic and detailed engineering to upgrade an existing biomass boiler with 57 MWt at MCR and to build a new thermal cycle with a turbo-generator 14.5 MWe capacity. The project included also the revamping engineering of the existing boiler with the installation of a new superheater, able to deliver higher steam temperature, the …

Repowering of biomass boiler in a chemical factory. Read More »